Understanding what is expected of the next generation of PET chemistry systems

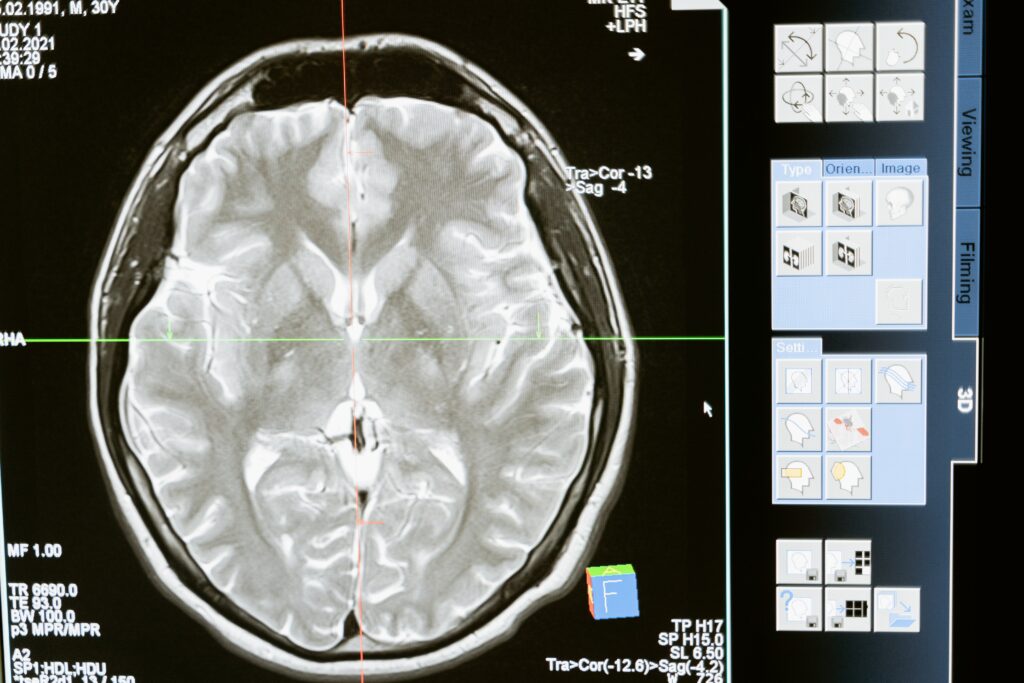

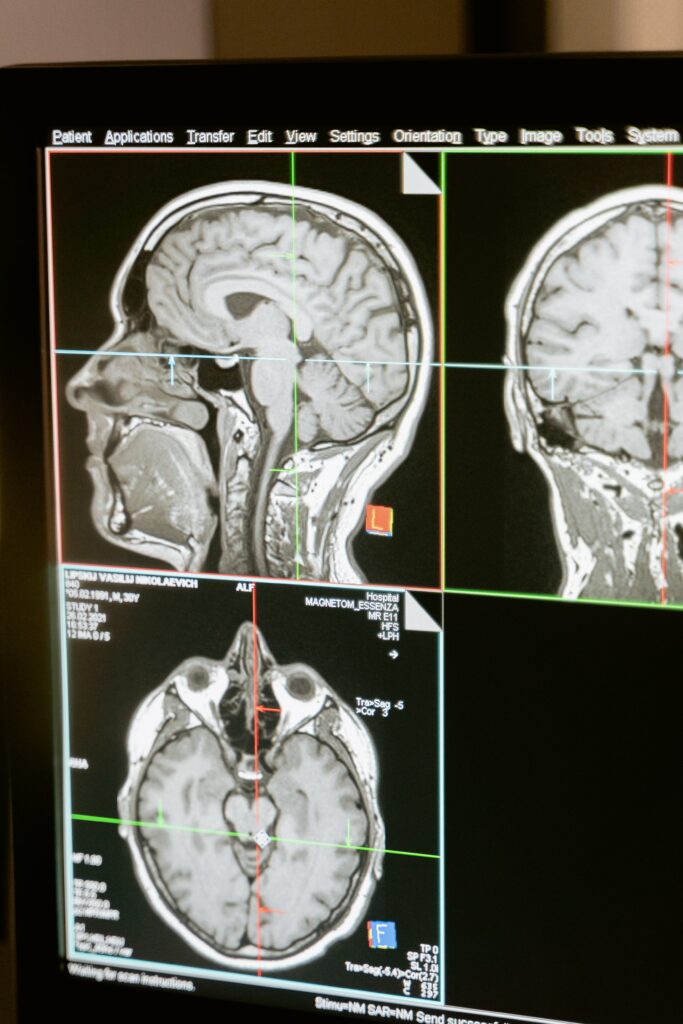

Our client was searching to understand what is expected in the near 3 to 5 years from the Positron Emission Tomography chemistry systems (synthesisers, quality control equipment, etc.). This is a high tech approach to image and diagnose brain tumours: a PET scanner identifies and tracks the patient’s brain activity by means of a specifically made tracer.

The question

For this study we needed to take a step back in order to understand what users thought of it. We looked for barriers and setbacks by certain laws or rules they have to follow – in order to come up with an overview of their unmet challenges.

We believed that this information would help understand the change they would like to see in the next generation.

Following this, our client could get to work and very pointedly start to refine their methodologies.

The end goal

The focus of this research wasn’t only on the technical features per se, but more on the solutions to efficiently synthesise the molecular imaging radionuclides required by the future targeted and immune therapies.

Our approach

For this case, we conducted 60 minute telephone interviews with heads of radiopharmacy, PET production managers/site directors and radiochemists/radiochemistry leaders. We talked to people in the USA (30 respondents), China (15 respondents), Japan (15 respondents), the UK (5 respondents), Germany (5 respondents), France (6 respondents), Sweden (4 respondents) and The Netherlands (5 respondents).

First of all, we asked the respondents for which purposes they were producing PET tracers. The most common purposes are clinical routines for patients within their own facility and for clinical studies or research. Most facilities were specialised in oncology and neurology, followed up by cardiology and theranostics.

Challenges

We asked them about their unmet expectations and biggest challenges, such as user-friendliness, versatility, reliability and maintenance and different capabilities.

Following that, we asked them about their thoughts on staffing (there isn’t much education on the topic so everything needs to be learned on the job), regulations (there are strict regulations and protocols to be followed), expenses (every tracer asks a great investment) and structural limitations (there are plenty of construction restraints when it comes to the infrastructure needed to produces PET tracers).

When looking at the overall responses, we saw challenges with recruiting staff and increased regulatory restrictions.

Following this, we asked them about their thoughts on the top barriers to handle the needed changes in order to come up with the next generation. Staffing and budget issues came out of this questionnaire, which lines up with their greatest pains.

What does the ideal next generation equipment look like?

We went back to the four greatest pains (technical, clinical, operational and economical) and asked them what they thought should change in order to come up with an improved version of the current equipment.

The respondents believed that an all-integrated versatile and flexible system would be an important aspect in both PET radiochemistry synthesisers and QC devices.

Following this, they mentioned that the gap between systems today and their future needs was the lack of an integrated versatile system, with all-round efficiency and ease of use.

The results

This research delivered some interesting results and insights, which made us capable of delivering our client some areas for improvement. Finding out their ideas concerning staffing, production, regulation and PET tracer growth, allowed us to discover their unmet expectations – and hereby their future needs and necessary components for future PET synthesiser and QC devices.